Prevent Relay Arcing using RC Snubber Circuits (1/2)

Arcing is a headace for relays at most of the time, it causes fault and reduces electrical life. Now we will disscuss potential formula and techniques of configuring RC circuit networks for controlling the arcing across relay contacts while switching heavy inductive loads.

Arc suppression

An arc is produced across the contacts when a switch or a relay is opened. With time, this condition can wear down the contacts.

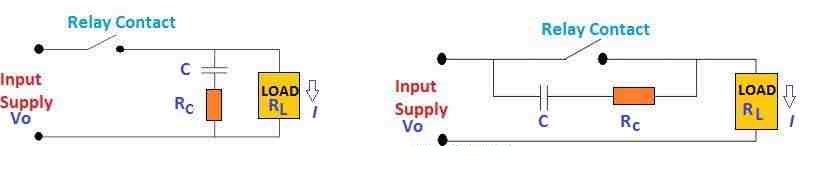

To overcome this problem, an Resistor/Capacitor or RC circuit is deployed across the contacts and safeguard them. Once the contacts are open, the applied voltage goes through the capacitor and not the contacts.

During the process, the capacitor charges up faster than the contacts opening time which eventually avoids an arc from forming across the contacts.

Inrush Current Suppression

When the contacts close, the inrush current from the charged capacitor and the supply voltage can be significantly higher than the ratings for the contacts thus causing them to worsen.

To prevent this, a resistor is introduced in series with the capacitor. It functions as a current limiter by absorbing the inrush current significantly thereby reducing the produced arc and extending the life of the contacts.

C.C Bates developed a formula for calculating the resistance and capacitance value that is required for the RC network: C = I2 /10, and Rc= Vo /[10I{1+(50/Vo)}]

The voltage induced at the contact opening can be determined by

V=IRc= (Rc/RL) Vo

- Where VO = Voltage source

- I = Load current at contact opening

- RC = Resistance of RC Snubber

- C = Capacitance of RC Snubber

- RL = Load Resistance

In our following examples we talk about the reed relay arcing issues, and try to evaluate the calculations required for designing RC networks across its contacts.

Since the principle of arcing may be the same in bigger relays also, the formulas used in reed relay could be also applied for dimensioning the RC networks for the bigger relays.

How Arcing Happens in Reed Relay Switching

A reed switch or reed sensor can be used for controlling an inductive device like a relay coil, solenoid, transformer, small motor etc.

When the reed switch opens, the charge stored in the inductance in the device will force the switch contacts to a high voltage. Once the switch opens, the contact gap is tiny in the beginning.

Therefore, arcing between the contact gap can happen almost immediately while the switch is just opening.

The phenomenon can occur in both resistive and inductive loads, but since the latter produce a higher voltage, increased arcing activity is seen thus reducing the switch life.

A diode is normally used by the DC inductive circuits to avoid high voltage. This type of diode is called the flyback, freewheeling, or catch diode.

Unfortunately, the application of this diode is not possible in AC circuits.

So, we must use a metal-oxide varistor (MOV), a bidirectional transient voltage suppressor (TVS) diode or an RC suppression network, also known as a snubber.

These diverse arc suppression approaches have many pros and cons. Not using suppression is also an option if the relay contact life isn’t affected without it.

The many factors that determines which approach needs to be undertaken, include cost, contact life, packing etc.

The fundamental reason for spark suppression circuit designs is to minimize arcing and the noise generated when engaging relays and switches.

to be continued…