Prevent Relay Arcing using RC Snubber Circuits (2/2)

RC Design Considerations

Using DC supply with TVS Suppressor Diode:

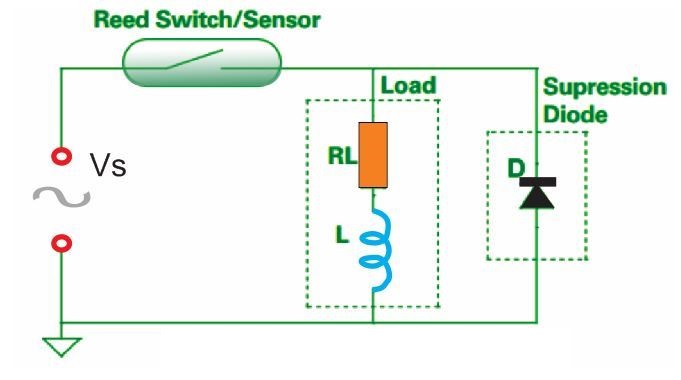

The MOV and TVS diodes conduct current when a threshold voltage is surpassed.

Normally, these diodes are parallelly connected to the switch contact. Even at low voltages like 24 VAC, these devices are capable of working efficiently.

Moreover, they can also function well at higher inductance 120 VAC loads. Compared to TVS diodes, MOV devices have added capacitance.

Thus, when an MOV device is utilized, you must consider the capacitance to be used. The Hamlin application note describes this scenario better.

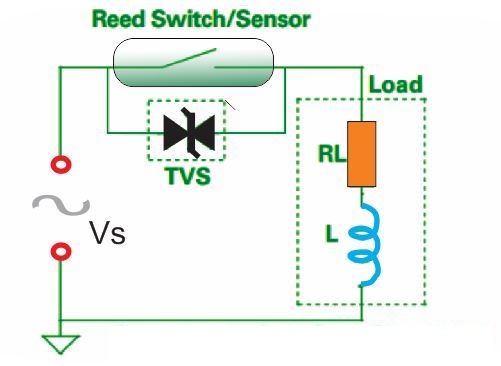

Using Bidirectional TVS Diode:

RC suppression had the edge because of limiting the switch contact voltage exactly during switch opening when the contact gap is small.

Furthermore, RC suppression can be implemented to lessen arcing and improve life in resistive loads.

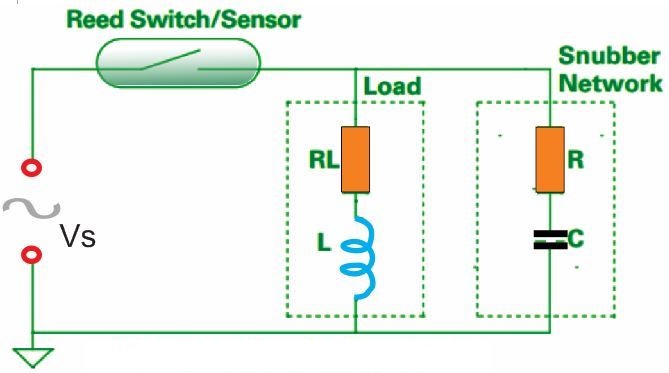

On an RC suppression circuit, a capacitor and resistor network connected in series is mounted across the switch contact in a parallel connection.

Another option is to place the capacitor and resistor across the load.

While attaching the RC snubber across the switch contact is ideal, there is a huge disadvantage because this creates a current path to the load when the switch is open.

If the snubber is installed across the load, it eliminates the current. However, changes in the connections and source impedance can affect the efficiency of the arc suppression.

Applying RC Snubber Parallel with the Switch Contact:

In the snubber, the values of the resistor and the capacitor are dependent on the requirement.

The chosen resistor must have a value high enough to restrict the capacitive discharge current when the contacts of the switch close. At the same time, it must be small enough to restrict the voltage when the switch contacts open.

If you choose a large capacitor value, it will surely decrease the voltage impact while the switch contacts opens.

But larger capacitor can be expensive and might cause higher capacitive discharge energy during the time the contacts of the switch close. This type applies to both DC and AC circuits.

Using RC (Snubber) Suppression Paralle with the Load:

Ohm’s law is applied to choose the most appropriate resistor value for the arc suppression.

In the Ohm’s law R = V/I, we apply the formula R = 0.5 (Vpk / ISW) and R = 0.3 (Vpk / ISW), where Vpk is the AC peak voltage (1.414 Vrms) and ISW is the rated switching current of the relay contact).

To decrease the contact degradation due to arcing, we have to make sure the R value is minimum. On the other hand, the R value must be increased to lessen the relay contact arcing due to the inrush current.

Determining the value of R in between these scenarios is the challenge.

You can begin with C = 0.1μF or 100 nF, when selecting the capacitor because this is standard value and thus cost-friendly. Depending on the performance examination of this capacitor, you can increase it until the capacitance is sufficient.

There are multiple methods to assess the performance of the chosen snubber values. Some can be performed just by calculation or simulation. However, the resistive and inductive features of the load may appear indefinite.

This is largely caused by the inductance of electromechanical loads that fluctuates when the components change positions.

It is a good practice to examine the voltage waveform across the switch contacts via an oscilloscope especially during contact opening. The snubber system should alleviate or at least minimize the arcing that happens when the contacts open and close.

The increasing voltage should not restart contact arcing. Furthermore, the maximum voltage across the capacitor in the snubber must not be more than it’s voltage rating.

Yet another way to find out if the snubber is working properly for a reed switch is to look at the switch contact gap and inspect the radiance of the light produced by the arc.

If there’s less light, that means the energy generating the arc is little and therefore warrants longer life.

The final and most precise method of examining the snubber’s performance is to conduct a life test.

Contact life is directly proportional to the number of switching cycles and not to the number of powered and unpowered hours.

It is advised to keep the maximum number of operations per second for life testing of arcing loads is around 5 to 50 operations per second.

This is around 5 to 50 Hz of maximum frequency. The number of tests you can carry out is reliant on the electrical load and the difference between convenience and precision.

When you need to find out the specifications of the components for the snubber, you must consider a few other things also apart from the described inspection of arc evaluation, highest capacitor voltage and life.

It is fundamental that when a switch contact is opened, current flows through the snubber circuit.

You must ensure that this current does not cause trouble to the snubber’s application. Moreover, it is essential to confirm that the power dissipation in the snubber’s resistor does not surpass its power rating.

One more thought is that an RC snubber circuit can be utilized in combination with a bidirectional TVS diode of MOV.

An RC snubber can be a highly efficient circuitry in limiting the initial voltage across the opening relay contacts, while the TVS or MOV may be a more efficient alternative for restricting peak surge voltages.

Reference: https://www.homemade-circuits.com/prevent-relay-arcing-using-rc-snubber-circuits/